TianGe Series Dual Cylinder Excavator Shear - Maximum Power for Metal and Steel Structures

The Dual Cylinder Excavator shear is a high-performance excavator attachment designed for cutting through tough rebar and steel structures. Equipped with a dual-cylinder system, it delivers significantly greater cutting force compared to standard eagle-beak shears. This makes it perfect for handling hard steel plates, rebar, and other high-strength materials in demolition and metal recycling applications. Its enhanced cutting power improves efficiency while meeting the demands of tough construction environments.

Watch the video on YouTube

Model & Specifications

| Model | DES- 100 | DES- 150 | DES- 290 | DES- 390 |

| Weight(kg) | 500 | 1100 | 2850 | 3300 |

| Opening length(mm) | 500 | 650 | 850 | 850 |

| Blade length (mm) | 400 | 500 | 670 | 670 |

| Height(mm) | 1360 | 1820 | 2350 | 2350 |

| Width(mm) | 810 | 1080 | 1350 | 1350 |

| Rated pressure(bar) | 180 | 240 | 300 | 300 |

| Rated flow rate(lpm) | 180 | 230 | 260 | 380 |

| Working pressure(bar) | 180 | 240 | 300 | 300 |

| Suitable for excavators(ton) | 6-9 | 13-16 | 20-30 | ≥30 |

Features:

Enhanced Shearing Power:

The double-cylinder design generates much higher shear force, allowing it to cut through thicker, more durable metal structures with ease. It performs exceptionally well as a hydraulic demolition shear cc series and concrete cutter.

High Efficiency:

With rapid cutting action, the **Dual Cylinder Excavator Shear** significantly speeds up construction and demolition tasks, reducing project times.

Versatile Performance:

This tool is suited for various applications such as building demolition, metal recycling, scrapped vehicle disassembly, and more. It also functions effectively as a concrete cracker and hydraulic crusher for primary demolition.

Precise Control:

Operators can easily control the cutting force and position using the excavator’s operating system, ensuring both safety and accuracy during complex tasks.

|

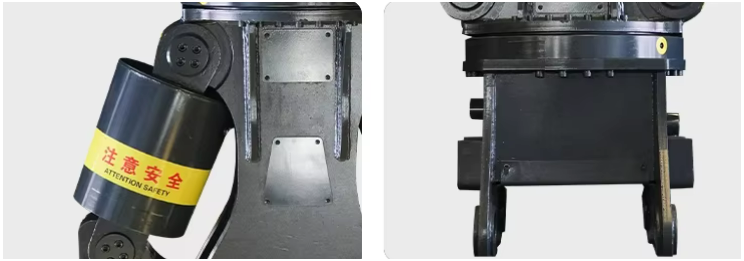

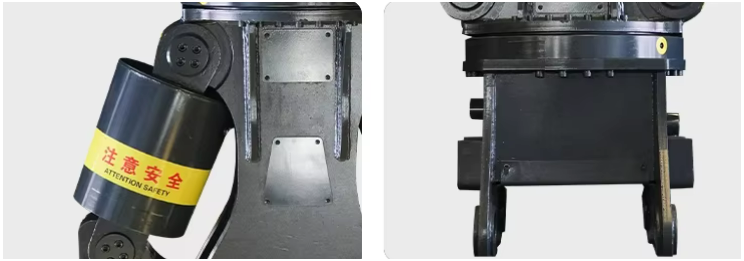

Sharp bladeThe unique shaped blade made of high toughness steel plate can be cut regardless of the thickness of the material. | Reasonably constructedEfficient oil cylinders can enhance the shear force of the jaws and reduce opening and closing time, thereby improving production efficiency. |

|

Durable and wear-resistantThe cutting body is made of imported HARD OX400 board, which has high toughness and wear resistance. | 360 degree rotationUsing dedicated rotary support and motor, it can rotate 360 degrees, with flexible operation, high efficiency, stable performance, and high torque. |

Applications:

Building Demolition:

Efficiently cuts through steel beams, rebar, and other structural components, making it an ideal hydraulic shears cutter for metal steel structure with max power.

Scrap Metal Recycling:

Cuts large metal waste into smaller, manageable pieces for easier recycling and transportation.

Emergency Rescue Operations:

The Dual Cylinder Excavator Shear can also be used in emergency scenarios to cut through obstacles, opening up paths for rescue teams.

The Dual Cylinder Excavator Shear is an excellent choice for heavy-duty hydraulic shears for excavators. With its ability to function as both a concrete cracker and concrete cutter, it offers unmatched power and versatility for any demolition or recycling project. Additionally, its role as a hydraulic demolition shear makes it a top-tier solution for demanding steel and metal cutting applications.

Frequently Asked Questions

What is a dual cylinder shear for excavator?+

A dual cylinder shear for excavators is a powerful attachment designed for cutting and processing various materials. It utilizes dual hydraulic cylinders to enhance cutting efficiency, making it suitable for demolition, scrap processing, and other heavy-duty tasks. These shear attachments can handle steel, concrete, and other tough materials with ease, providing excellent performance in various applications.

How does a hydraulic shear for excavators operate?+

A hydraulic shear for excavators operates by using hydraulic pressure to power its dual cylinders, which effectively cut through materials. The hydraulic system allows for precise control and adaptability to different tasks, making it ideal for both demolition and recycling projects. With this technology, the shear can quickly slice through metals and concrete, streamlining the process and improving efficiency.

What are the benefits of using a dual cylinder cutter for heavy machinery?+

The benefits of using a dual cylinder cutter for heavy machinery include increased cutting power, improved speed, and enhanced durability. These cutters are specifically designed to withstand tough conditions and provide reliable performance in demanding environments. Furthermore, they reduce operational downtime, allowing operators to complete projects faster while minimizing costs.

How to choose the right excavator shear attachment for my needs?+

When choosing the right excavator shear attachment, consider factors such as the type of materials you’ll be cutting, the weight class of your excavator, and the shear’s specifications. Look for a dual cylinder shear that matches your machine's capabilities and is suited for your specific tasks, whether they are demolition, recycling, or construction. Ensuring compatibility will maximize efficiency and performance.

What materials can a dual cylinder hydraulic shear cut?+

A dual cylinder hydraulic shear can cut a wide range of materials, including steel, concrete, and other hard substances. Its robust design enables it to handle challenging jobs, such as scrap processing and demolition work. Depending on the model, these shears can even manage thicker materials, making them versatile tools for contractors and operators in various industries.

Are dual cylinder shears suitable for demolition projects?+

Yes, dual cylinder shears are highly suitable for demolition projects. Their powerful cutting capability allows them to efficiently process structures and materials on site. By utilizing a dual hydraulic cylinder system, these shears can slice through rebar and concrete with precision, making them ideal for contractors involved in large-scale demolition and renovation work.

What maintenance is required for hydraulic shearing tools?+

Maintenance for hydraulic shearing tools typically includes regular inspections of hydraulic fluid levels, checking for leaks, and ensuring the cutting edges are sharp and free from debris. Additionally, it’s essential to lubricate moving parts to keep the dual cylinder shear operating smoothly. Regular maintenance will prolong the life of your attachment and ensure optimal performance during use.

How much does a dual cylinder shear for excavators cost?+

The cost of a dual cylinder shear for excavators can vary significantly based on factors such as brand, size, and features. Generally, prices can range from several thousand to tens of thousands of dollars. Investing in a high-quality shear attachment is crucial, as it can enhance your machine's capabilities and improve efficiency in cutting and demolition tasks.

What are the common applications of dual cylinder excavator shears?+

Common applications of dual cylinder excavator shears include demolition, scrap processing, and cutting through heavy steel structures. They are frequently used in construction sites, recycling facilities, and by contractors needing to manage tough materials. Their versatility makes them valuable tools for operators tackling a wide array of projects.

How can I enhance the performance of my excavator shear attachment?+

To enhance the performance of your excavator shear attachment, ensure that your hydraulic system is properly calibrated and maintained. Regularly inspect and sharpen the cutting edges to improve efficiency, and match the shear with an appropriately sized excavator for optimal power. Utilizing the right techniques during operation can also maximize effectiveness and longevity.